Complete integration of gearboxes and digital technology

01Following the latest trends in scientific and technological innovation, we have thoroughly integrated our main business of gearboxes for mechanical equipment with digital technology. The company has independently developed a high-precision acquisition system comprised of software and hardware, creating the GearSight IoT cloud platform for gearbox health status monitoring and diagnosis. In this way, the state of the gearbox can be monitored and managed throughout its lifetime, providing customers with services such as health status monitoring, early warning, diagnosis and maintenance of the whole transmission chain.

Integrated innovation has created the GearSight cloud platform - ngcyun.com

02Making full use of our technical process, we have achieved integrated innovation in various fields, constantly improving our product R&D and service capabilities. By introducing technologies such as CMS status monitoring, cloud computing, big data analysis, IoT, AI, electronic circuits, edge computing and mobile terminals, we can now offer the GearSight IoT cloud platform for gearbox health status monitoring and diagnosis. This allows gearboxes to be monitored and managed throughout their entire lifecycle.

Full-Lifecycle monitoring and diagnosis of the transmission chain

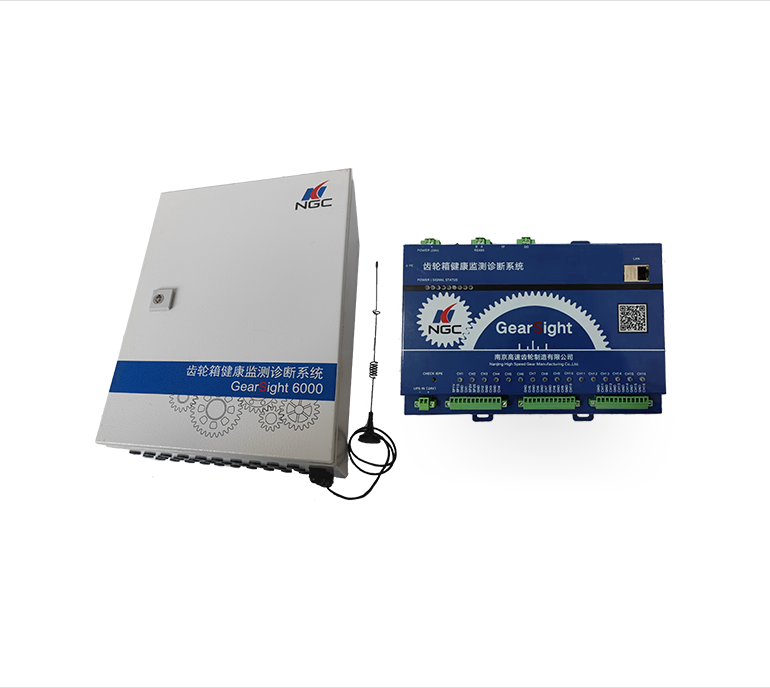

03Our various proprietary software systems, such as the GearSight system and the NGC Cloud, can be combined with multi-channel, high-precision, high-frequency circuit hardware units for synchronous data collection, along with other products such as wind energy and industrial gearboxes. In this way, we can provide users with a variety of services, including the digital factory, health status monitoring, early warning, diagnosis, and maintenance of the whole transmission chain.

Cost-effective GearSight solutions

04In the future, we will continue to invest in research and development and engage in further independent research. We will upgrade both software and hardware, as well as fault diagnosis and early warning algorithms, and improve our capabilities in product R&D and services. In this way, we will be able to provide our customers with cost-effective GearSight series products and services, further enhancing their market competitiveness.

With a dedicated hardware and software R&D team, we can provide a full range of cost-effective GearSight products for monitoring and diagnosis.

Our gearbox analysis team features a five-dimensional expert consultation mechanism, and is able to provide transmission chain monitoring and diagnostic services based on CMS data (including third-party data).

Relying on our in-depth understanding of the gearbox and accumulated test data, we can provide big data AI diagnosis and customized services based on a black box model.

We provide training and certification for GearSight diagnostic analysts. By helping our customers master the necessary techniques, gearbox abnormalities can be discovered early to reduce potential loss.

Relying on our gearbox R & D, manufacturing, testing, monitoring and maintenance base, we can provide a full set of lifecycle services for your gearbox, including professional maintenance and repair services.

The system can support 16 vibration channels and 2 rotational speed channels, with sampling frequencies up to 256KHz. 24-bit high-resolution ADC chip level multi-channel synchronous acquisition is used.

Capabilities and can monitor up to 16 temperature channels and 8 analog signal channels in the 4-20mA range.

MOREThe protection level of the acquisition station is IP65, and that of the sensor is IP68. They have passed certification for a variety of reliability tests and can adapt to a wide range of harsh working conditions and environments.

Instrument level circuit design is used, achieving peak-to-peak noise values of around 0.1mV (0.002m/s2), with a dynamic range of nearly 100db. At the same time, a highly sensitive acceleration sensor further improves its abilities to acquire and identify weak vibration signals.

The system supports 16 vibration channels and 2 rotational speed channels, with sampling frequencies up to 256KHz. 24-bit high-resolution ADC chip level multi-channel synchronous acquisition is used. The vibration and speed signals of the gearbox can be collected and monitored synchronously to achieve good noise reduction.

The system features a complete self-diagnosis function, meaning it can be installed on-site and carry out self-diagnosis at the click of a button, with no need for extra installation and commissioning.

The system provides offline data storage through a built-in EMMC with a capacity of 4G and an external TF card with a capacity of 32G. In the case of a network fault, the acquisition station can collect important data automatically and store it continuously.

The system features trigger collection, manual acquisition, and timed acquisition, making sure that no key data will be lost.

Features a dual-core ARM architecture, with a memory of 512Mb and a parallel FPGA computing chip to ensure outstanding edge computing performance and scalability.

Supports various communication modes, including cable networks, fiber optic networks, WIFI, and 4G, and features a remote firmware upgrade to sustain updates to the software algorithms.

Which support full WIFI/4G network connectivity.

The gateway is equipped with industrial grade wireless routing and an industrial grade DC isolated power supply.

The wireless sensor features WIFI networking to enable collection and transmission of spatial triaxial vibration acceleration signals and temperature data.

MOREThe system supports multiple forms of network transmission, and features a distributed architecture.

The high-performance industrial grade 32-bit communication processors and industrial grade wireless modules feature an embedded real-time operating system as a software support platform. One RS232 (or RS485), one Ethernet LAN, one Ethernet WAN, and one WIFI interface are available for connecting with various devices to achieve transparent data transmission and routing.

The wireless sensor uses WIFI networking, which is compatible with the digital factory WIFI network, enabling the collection and transmission of spatial triaxial vibration acceleration signals and temperature data. The installation is very flexible, and can be fixed with a magnetic holder or by threading.

The gateway is equipped with omnidirectional antennas to expand its coverage. The sensor nodes can collect temperature and vibration signals from gearbox measurement points in real time, and send this data and any other relevant information to remote platforms through the Internet.

The low-power design enables the system to operate at low frequencies for one year without needing to replace the batteries. In addition, the system features a detachable battery design, making it easy for users to replace the batteries themselves in high-frequency applications.

The GearSight Portable Gearbox Health Monitoring and Diagnostic System is a high-end testing device that combines cutting-edge technology with industry expertise.

It is suitable for rapid inspections on factory floors, precise support during after-sales service, and in-depth data analysis in academic research.

MOREPortable and Easy to Use: Designed with a portable trolley case, it is equipped a full-network 4G router, a 24V high-performance lithium battery and open data interfaces, allowing for rapid deployment in various scenarios and seamless integration into different manufacturing environments.

Accurate Monitoring: Featuring high-precision speed sensors, broadband and low-frequency vibration sensors, and the built-in GearSight data acquisition core unit, as well as accessories such as magnetic bases and sensor cables for vibration acceleration and speed, the system provides real-time, accurate status monitoring of gearboxes and rotating mechanical transmission chains.

Multi-channel Synchronous Acquisition: Featuring a built-in FPGA acceleration chip, the system is capable of simultaneously processing 16 vibration channels and 24-bit high-resolution ADC data, enabling chip-level multi-channel synchronous acquisition.

Intelligent Diagnosis: Featuring built-in advanced algorithms and diagnostic models, the system analyzes all collected data to ensure early fault warning and precise diagnosis, providing a scientific basis for equipment maintenance.

The GearSight gearbox diagnostic analysis software is mainly used for the post-processing of data.

The system offers more than 20 data analysis methods, including time-domain waveforms, frequency spectrums, cepstrums, envelope demodulation, cross phase, waterfall plots, and trend charts.

The system can be used to inspect a trend chart, which can classify and collect data, including vibration and impact information, based on conditions such as speed, power and load.

MOREA team of diagnostic experts holding ISO 18436 Level III International Vibration Analyst Certification provides 24-hour uninterrupted care.

Diagnostic assistance from senior engineers with over ten years of experience in data analysis, design, manufacture, inspection and after-sales service.

The online warning mechanism, composed of constantly updated AI machine learning model and expert gear diagnostic systems, makes the early warning and diagnosis of equipment more accurate and efficient.

苏ICP备09040484号 ©Nanjing High Speed & Accurate Gear Group Co.,Ltd.